Understanding Pressure & Temperature Circular Chart Recorders – Applications & Uses Across Industries

In today’s industrial environment, monitoring pressure and temperature is critical to maintaining safety, efficiency, and compliance. One of the most time-tested and reliable instruments used for this purpose is the Circular Chart Recorder. These recorders provide a visual, continuous record of pressure and/or temperature over a set time interval, making them ideal for a variety of industrial applications.

Circular chart recorders are available in two main types based on the drive mechanism:

- Mechanical Motor-Driven Recorders

- Electrical Motor-Driven Recorders

Let’s explore the features, applications, and benefits of each type across various industries.

🔧 What is a Circular Chart Recorder?

A circular chart recorder records temperature, pressure, or both on a round chart that rotates over a specific time frame (e.g., 24 hours, 7 days). A pen or stylus continuously plots the readings on the chart, providing a real-time historical data log.

⚙️ 1. Mechanical Motor Circular Chart Recorder

How it works:

Operates using a spring-wound or battery-powered clock motor. It’s simple, robust, and does not rely on external electrical power.

✅ Common Applications:

🔹 Oil & Gas Industry:

- Monitoring pressure in pipelines and wellheads

- Logging data for safety audits and inspections

🔹 Food & Beverage:

- Recording temperatures in ovens, cookers, and refrigeration units

- Ensures HACCP compliance for food safety

🔹 Pharmaceuticals:

- Controlled temperature monitoring in stability chambers

- Used in areas where digital recorders are not suitable

🔹 Industrial Boilers:

- Tracks boiler pressure and temperature trends

- Assists in optimizing combustion and load cycles

✅ Advantages:

- No reliance on power supply

- Simple to operate and maintain

- Suitable for remote locations

⚡ 2. Electrical Motor Circular Chart Recorder

How it works:

Powered by an electric motor (typically 230 VAC or 24 VDC). Offers consistent chart rotation and often supports multiple sensors.

✅ Common Applications:

🔹 Chemical & Petrochemical Plants:

- Monitoring of batch reactions where pressure and temperature vary with time

- Helps prevent overheating or overpressure scenarios

🔹 Environmental Monitoring:

- Tracking temperature and pressure in test chambers and cleanrooms

- Ensures environmental stability for sensitive processes

🔹 Cold Storage & Warehouses:

- Ensures consistent refrigeration conditions

- Provides recordkeeping for audits and insurance

🔹 Process Industries:

- Used in fermentation, drying, distillation units, etc.

- Enhances process control and data integrity

✅ Advantages:

- More stable and accurate timekeeping

- Ideal for continuous monitoring

- Can be interfaced with alarms and control systems

🏭 Industry-Wide Importance

Regardless of the motor type, circular chart recorders continue to play a key role in:

- Compliance: Meeting audit, validation, and regulatory requirements (FDA, ISO, etc.)

- Quality Control: Maintaining product quality and process consistency

- Safety: Preventing equipment failure due to abnormal pressure/temperature

- Data Traceability: Providing historical logs for analysis and reporting

🧰 Choosing the Right Recorder for Your Application

When selecting a chart recorder, consider:

- Measurement type (pressure, temperature, or both)

- Number of pens (single or dual)

- Time range (24 hr, 7 day, etc.)

- Environment (indoor, outdoor, hazardous)

Whether you opt for mechanical or electrical motor-driven recorders, both serve as reliable tools to monitor critical parameters with visual clarity.

Need help choosing the right chart recorder?

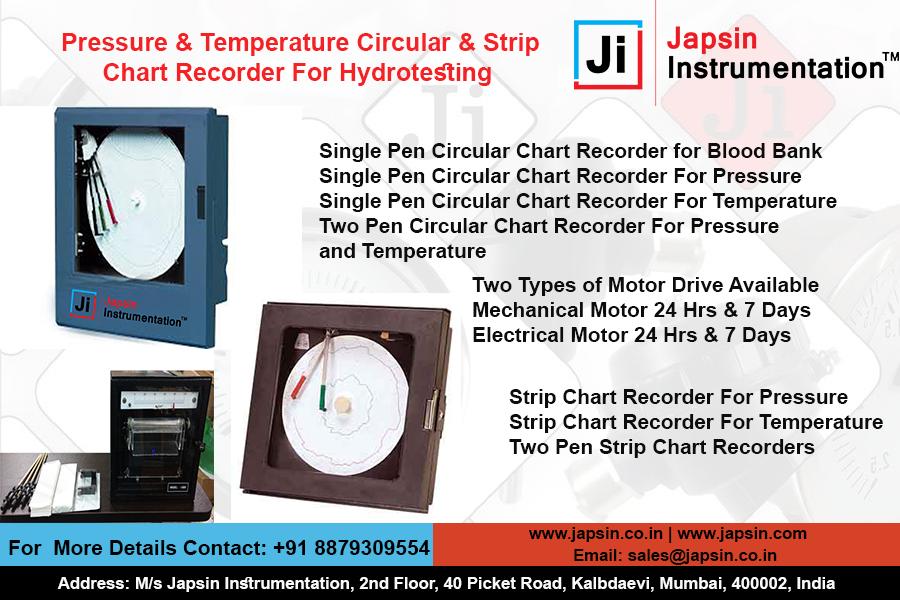

We at Japsin Instrumentation specialize in pressure, temperature, and calibration instruments, offering a wide range of chart recorders to suit your industry requirements.

📞 Contact us today at +91-8879309554 or visit www.japsin.com for expert guidance.