Level Gauges & Level Instruments: Purpose, Applications, Types, Quality

In industrial sector, precision in measurement is not just a preference—it’s a necessity. Among the most critical measuring tools used across multiple industries are Level Gauges and Level Instruments.

These devices help in monitoring and controlling the level of liquids, solids, or slurries inside tanks, vessels, or silos.

Their reliability and accuracy directly impact operational safety, efficiency, and productivity.

What Are Level Gauges & Level Instruments?

Level Gauges are mechanical or electronic devices used to visually or electronically indicate the level of a substance in a container.

Level Instruments encompass a broader category that includes sensors, switches, transmitters, and digital indicators that measure and transmit the level data to control systems.

Purpose of Level Gauges & Instruments

- Monitoring: Ensure real-time knowledge of fluid or solid levels in process tanks or containers.

- Control: Help automate processes based on level thresholds.

- Safety: Prevent overflow, dry-run conditions, or hazardous spillages.

- Inventory Management: Accurate measurement assists in efficient stock control.

- Compliance: Essential for adhering to industry safety and environmental regulations.

Applications Across Industries

Level Gauges and Instruments are used in diverse sectors, such as:

1. Oil & Gas

- Tank farms, separators, and storage units

- Ensuring correct levels of fuel, crude, or chemicals

2. Pharmaceuticals

- High-precision monitoring in clean and sterile environments

3. Water Treatment

- Monitoring water levels in treatment plants, reservoirs, and tanks

4. Chemical & Petrochemical

- Handling aggressive, corrosive, or high-temperature fluids safely

5. Food & Beverage

- Level monitoring in brewing, dairy, and bottling operations

6. Power Plants

- Boiler water level measurement and fuel tank monitoring

Types of Level Gauges & Instruments

Level measuring devices are classified into mechanical and electronic types:

🔹 Mechanical Level Gauges

- Sight Glass (Tubular/Reflex/Transparent): Direct visual level indication

- Float & Board Type: Widely used in large tanks and storage vessels

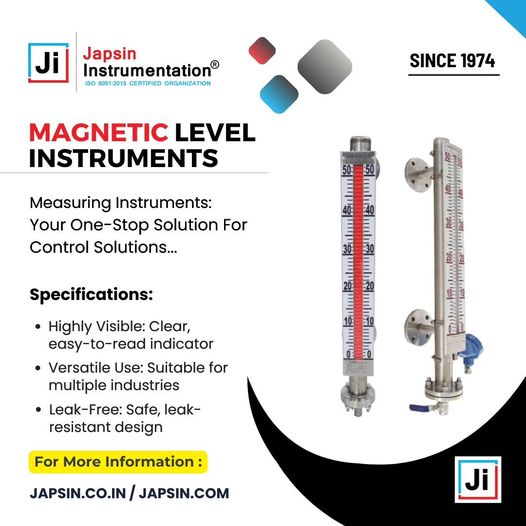

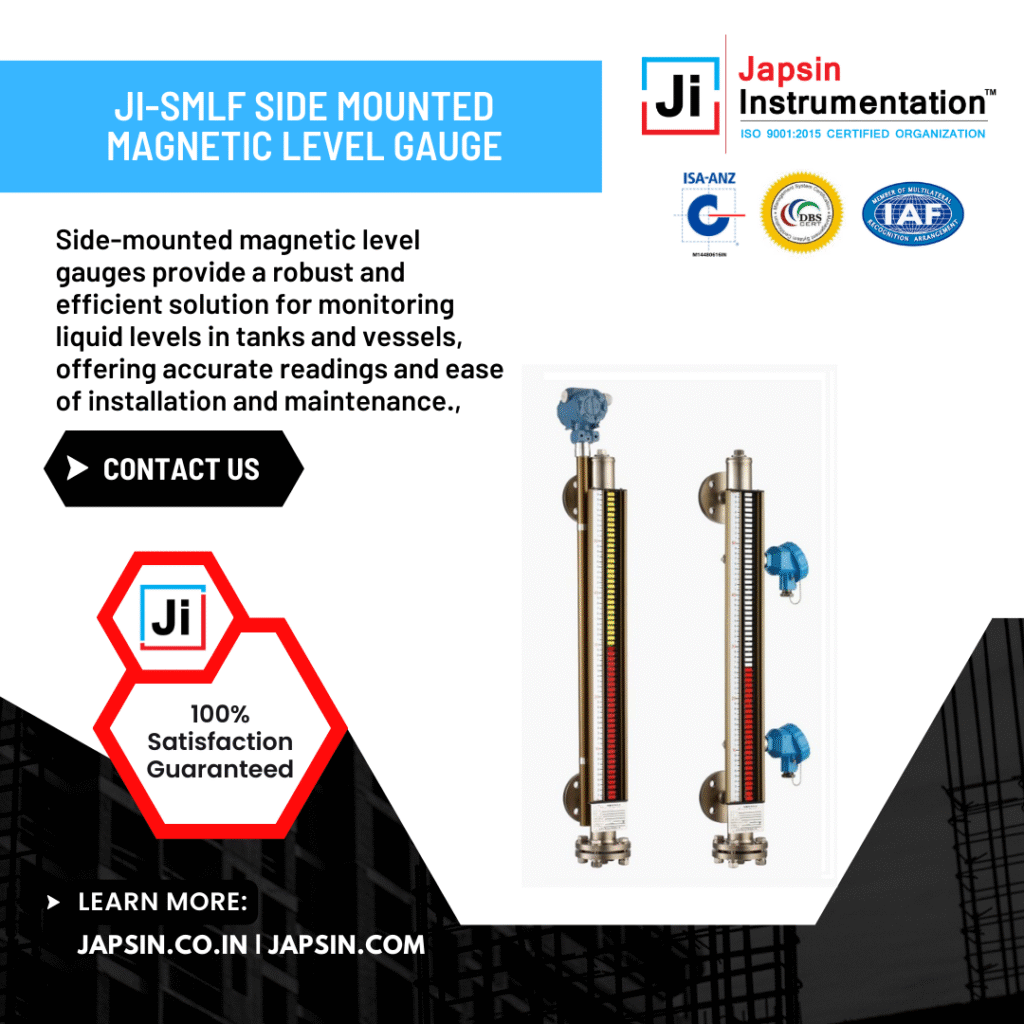

- Magnetic Level Gauges: Uses float with a magnetic system for clear visual indication

🔹 Electronic Level Instruments

- Ultrasonic Level Transmitters: Non-contact, ideal for corrosive or slurry materials

- Radar Level Transmitters: High-precision, used in complex and high-pressure tanks

- Capacitance & Conductivity Sensors: Suitable for liquids with varying conductivity

- Hydrostatic Level Transmitters: Measures pressure exerted by the liquid column

- Vibrating Fork & RF Admittance Switches: Ideal for point-level detection

Quality Considerations

When selecting a level gauge or instrument, quality assurance is paramount. Consider the following:

- Material Compatibility: Must match the medium’s chemical properties (e.g., SS316 for corrosive liquids)

- Pressure & Temperature Ratings: Must withstand the operating conditions

- Certifications: Look for ATEX, SIL, ISO, and CE certifications for safety compliance

- Repeatability & Accuracy: Critical in precision applications like pharmaceuticals

- Maintenance & Longevity: Choose models that offer easy maintenance and long service life

Conclusion

Level Gauges and Instruments are integral to modern industry, ensuring operational continuity, safety, and efficiency. With technological advancements and rising automation, the market is steadily moving towards smart, reliable, and maintenance-free solutions. Whether you’re managing a power plant or a dairy processing unit, investing in quality level measurement devices can significantly enhance process control and profitability.