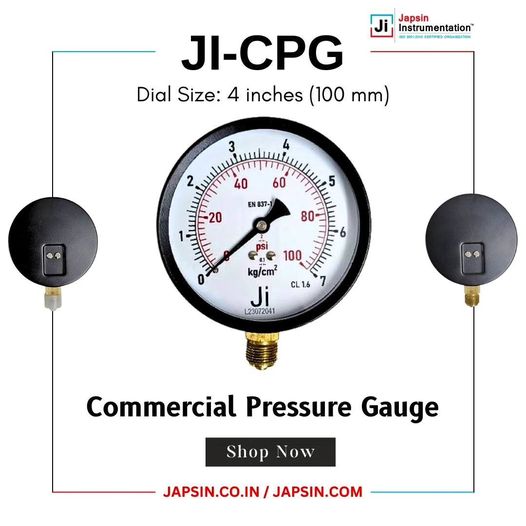

Pressure Vacuum Compound Gauges: Precision, Reliability, and Versatility

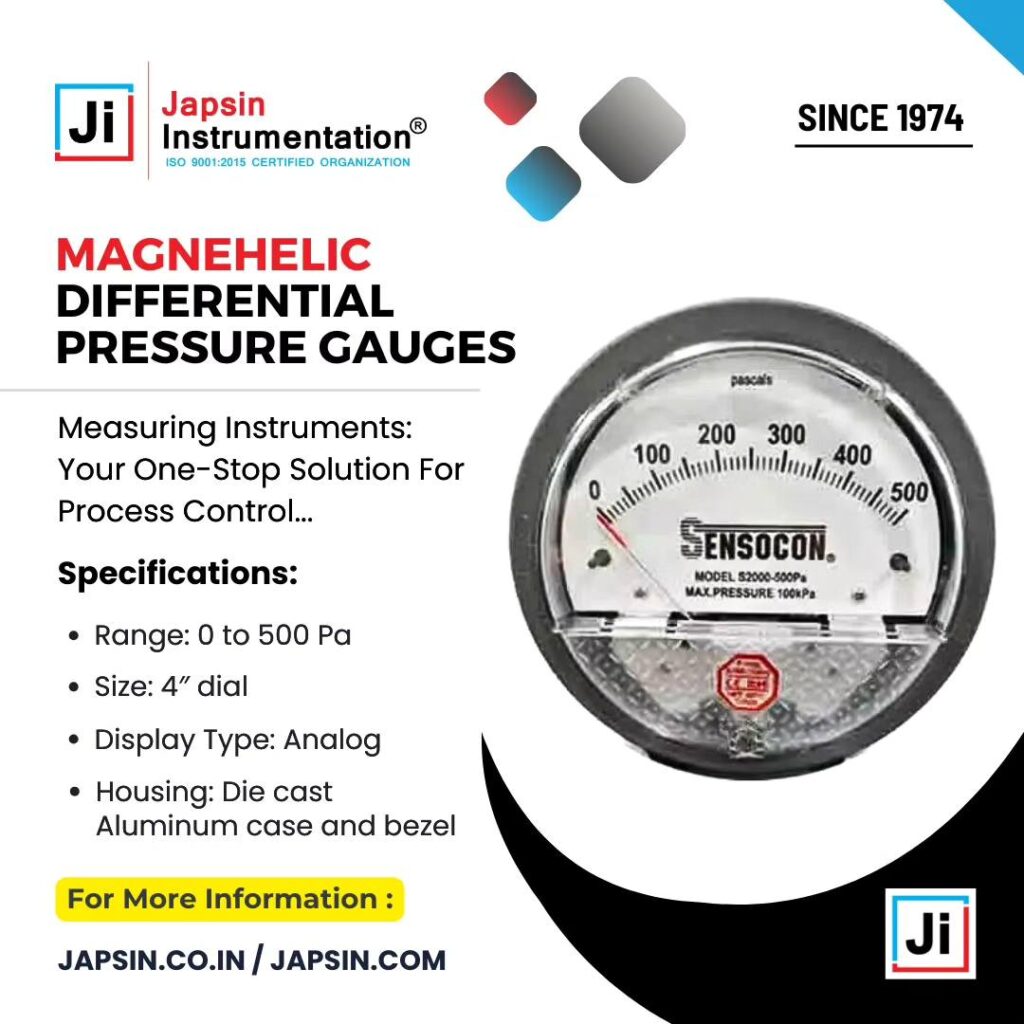

At Japsin, we specialize in manufacturing high-quality Pressure Vacuum Compound Gauges designed for a wide range of industrial applications. Our gauges are built with precision engineering, ensuring accurate pressure and vacuum measurement for various systems.

.

Why Choose Japsin Pressure Vacuum Compound Gauges?

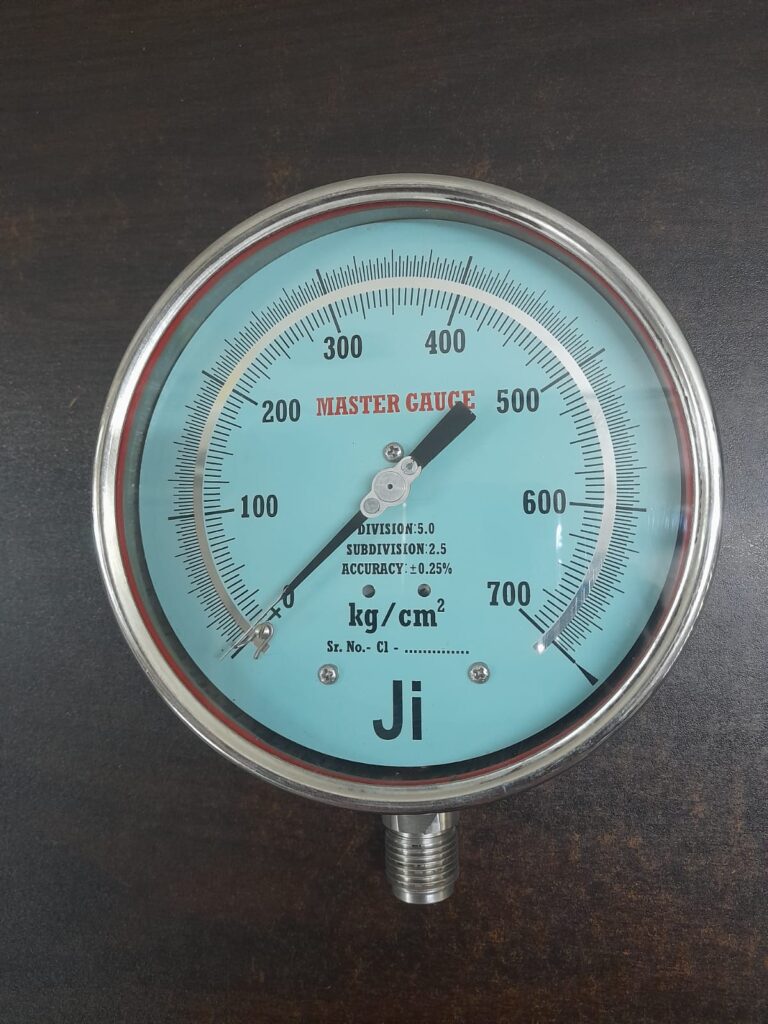

- Superior Accuracy – Our gauges provide highly accurate readings to ensure system efficiency and safety.

- Durability & Reliability – Made from high-quality materials, Japsin gauges withstand harsh environments and heavy usage.

- Wide Measurement Range – Suitable for both vacuum and pressure applications, making them highly versatile.

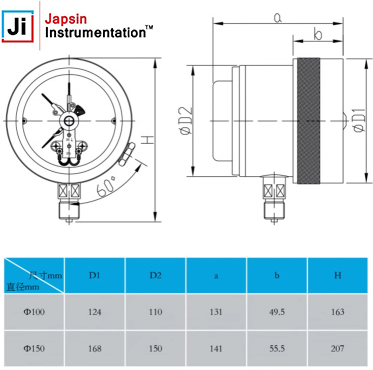

- Customizable Solutions – Available in different sizes, dial configurations, and connection types to meet specific industry requirements.

Japsin Quality Assurance

We are committed to delivering superior quality products that meet global industry standards. Every Japsin gauge undergoes rigorous testing and quality control procedures to ensure reliability and long-lasting performance.

Features of Japsin Pressure Vacuum Compound Gauges:

- Stainless steel or brass construction for corrosion resistance

- High-impact resistant dial glass for durability

- Dual-scale readings for convenience

- Various mounting options for easy installation

- Compliance with international safety and quality standards

Applications of Pressure Vacuum Compound Gauges

Japsin’s compound gauges are ideal for multiple industries, including:

1. HVAC & Refrigeration Systems

Used for monitoring pressure and vacuum levels in air conditioning and refrigeration systems, ensuring optimal performance and efficiency.

2. Chemical & Pharmaceutical Industry

Essential for measuring vacuum levels in chemical processing and pharmaceutical production, ensuring precision in sensitive operations.

3. Hydraulic & Pneumatic Systems

Monitors pressure variations in hydraulic machinery and pneumatic equipment, ensuring smooth and safe operation.

4. Food & Beverage Industry

Used in food processing plants to maintain vacuum and pressure control in packaging and production lines.

5. Oil & Gas Sector

Crucial for monitoring vacuum and pressure levels in oil refineries, pipelines, and gas processing plants.

6. Power Plants & Boilers

Ensures safe and efficient operation of boilers and steam-based systems by monitoring critical pressure levels.

Location

Registered Office:

Room no 8, Second floor, Neelam Building 40-46 kesar niwas Picket road, road, Kalbadevi, Mumbai, Maharashtra 400002

Landline No: +91-22-22065104 / 22059501

Branch Office:

Unit No 35, 2nd Floor Sumtinath Industrial Premises Co-op Soc Ltd Chincholi Bunder Road, west, off New Link Road, Mindspace, Mumbai, Maharashtra 400064

Landline No: +91-22-46003034

Pages

Follow us