Japsin Instrumentation / Ravika Dead Weight Tester (DWT) is so named because it uses calibrated dead weights to measure and verify pressures in a closed and compressed fluid system. This designation arises from the principle that for each specific pressure to be applied within the hydraulic system, a corresponding fixed weight is used to counteract buoyancy forces. Each weight is marked with its equivalent force, which is applied to a predefined piston-cylinder area. Thus, the term “Dead Weight Tester” is derived.

Working Principle

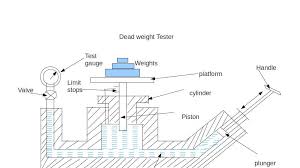

The operation of a DWT is based on Pascal’s Law, which states that in a closed system filled with an incompressible fluid, any applied pressure is uniformly distributed in all directions. In the DWT system, silicone oil serves as the incompressible fluid within the piston-cylinder arrangement, piping, pressurization chamber, and the head where the gauge to be calibrated is mounted.

Initially, silicone oil is introduced into the pressurization chamber from the oil reservoir, and all trapped air is carefully vented to ensure accuracy. This step is crucial because air, being compressible, could interfere with uniform pressure distribution, leading to errors.

Once the system is air-free and filled with oil, pressure is gradually increased from the pressurization chamber. The oil pressure rises uniformly throughout the system, including in the piston-cylinder arrangement where the dead weights are mounted. As the upward force exerted by the oil pressure equals the downward force of the weights, equilibrium is achieved, and the weights begin to lift.

At this point, the pressure in the system is precisely equal to the force applied by the weights divided by the effective piston area. The gauge or transmitter under calibration is adjusted accordingly. This process is repeated for different pressure levels—commonly at 0%, 25%, 50%, 75%, and 100%—to verify linearity and repeatability.

Formula

The fundamental formula for DWT operation is:

p= F / A

Where:

- p: Reference pressure

- F: Force applied by the dead weights

- A: Effective area of the piston-cylinder unit

For accurate measurements, this formula is further refined to account for factors such as buoyancy, local gravity, and thermal expansion of components.

This process ensures precise calibration of pressure gauges and transmitters,